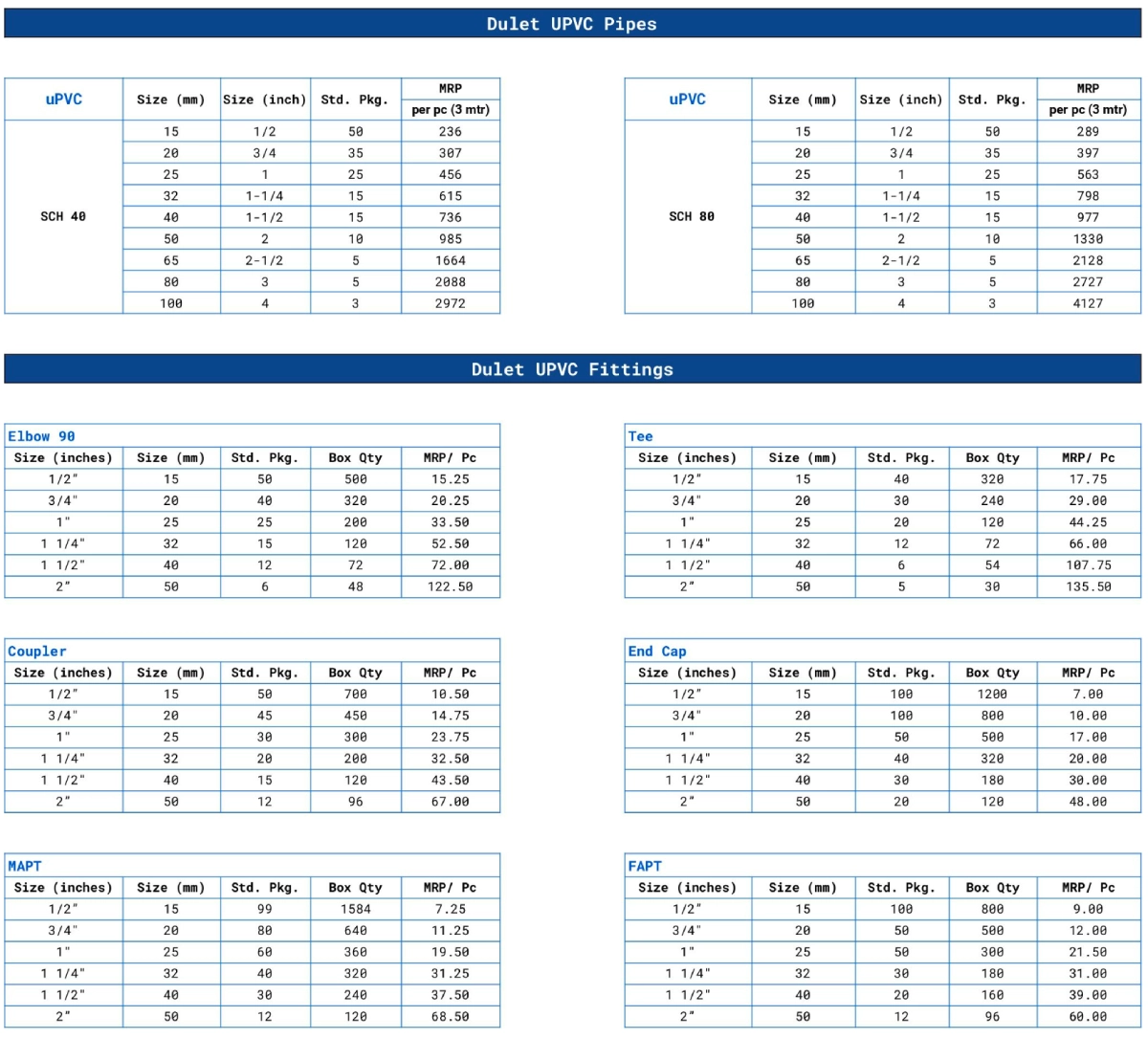

About Dulet UPVC Pipes and Fittings

Dulet UPVC pipes are lead-free, thus ensuring a safe and clean environment for portable water. They are easy to fit and economical for water distribution. These pipes are fabricated according to the ASTM D1785 standard and are available in two variants – SCH 40 and SCH 8.